Camlock Coupling

Camlock Coupling

Camlock Coupling

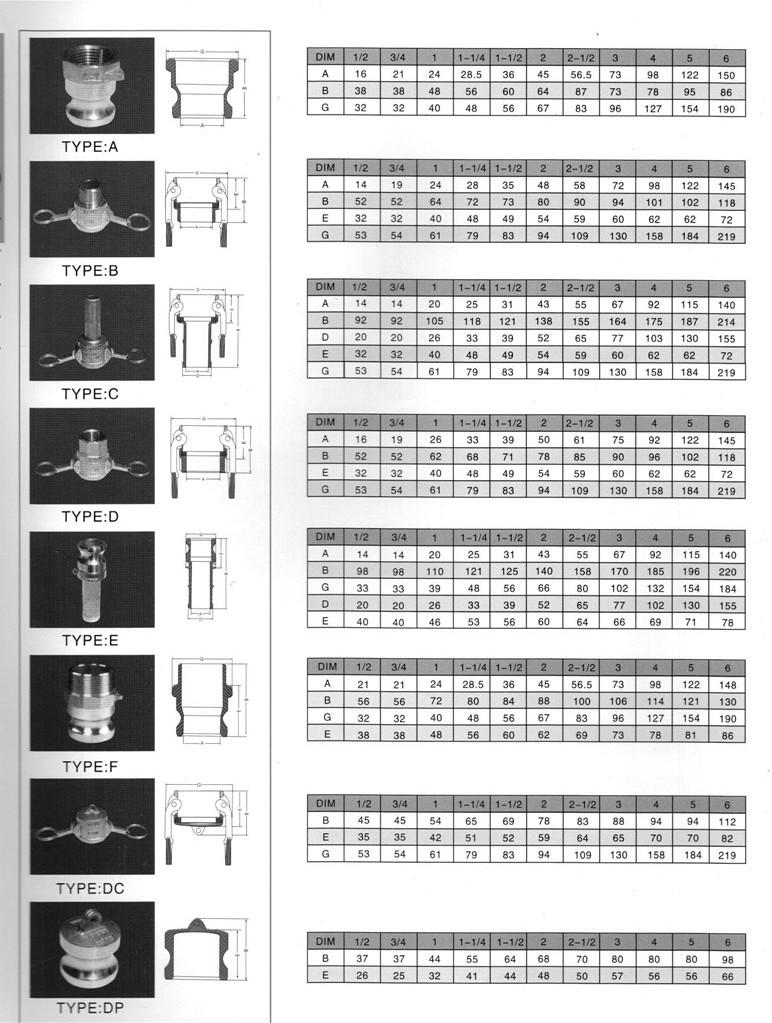

Cam & Groove Couplings/Kamlok Couplings

MIL / EN / DIN

Camlocks are also known as Cam and Groove Couplings. This is because they are engineered with grooves that allow the various styles to fit together creating a tight seal.Their simple structure and easy operation make them very popular. Camlocks are connected by simply opening the coupler arms and inserting the adaptor into the coupler. As the arms are pushed down to the sides, the two connectors are forced tightly together creating the bonded seal on an internal gasket. Used where quick, convenient connection and disconnection of piping and hose is required.Kigo Camlock come in a variety of materials: aluminum, stainless steel, brass, polypropylene.

Standard:

1.MIL A-A-59326

Cam & Groove couplings are made in compliance with A-A-59326 (old version called MIL-C-27487) specification.

2.EN14420-7(DIN2828)

The European standard EN 14420-7:2004 replaces DIN 2828, which was applied to cam & groove couplings manufactured to A-A-59326A.A flat thread seal has been added to the female threaded parts ,and a smooth hose shank has been added for assembly with DIN 2817 safety clamps.

Size:

●Aluminum:1/2″ to 8″

●Stainless steel:1/2″ to 6″

●Brass:1/2″ to 6″

●PP:1/2″ to 4″

Material:

1.Stainless steel AISI316/1.4408 by investment casting

2.Brass CW614N by forging

3.Aluminium by Die casting or gravity casting

4.Polypropylene or Nylon

Features:

1. Handles are made of stainless steel AISI 304 as a standard.

2. Camlocks are capable of transporting liquids,solids and gases,except liquid gas and steam.It was widely used to Petroleum industry,Mining industry,Irrigation industry,Chemical industry(Transportation for oil/water).

3. Coupling with multi-serrated hose shank & collar are available on customer’s request.

4.The threads are according to ISO228,BSP or NPT