Spiral Wound Gasket

Spiral Wound Gasket Applications

Spiral Wound Gaskets are one of the best all-around seals, offering a low-cost solution that combines fire resistance and the ability to handle temperature and pressure fluctuations. Multiple wraps of metal and filler in the spiral create barriers that reduce the possibility of leaks. Widely used throughout refineries and chemical processing plants, spiral wound gaskets are also effective for power generation, aerospace, and a variety of valve and specialty applications.

Spiral Wound Gaskets are available with standard fillers of ceramic, flexible graphite, PTFE, or mica graphite. Additionally, Flexitallic has a proprietary. high temperature sealing material – Thermiculite® that ensures against thermal oxidation at temperatures in excess of +1800°F.

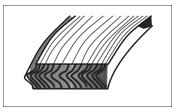

Style CG: Utilizes an external ring which accurately centers gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges up to and inclusive of class 2500.

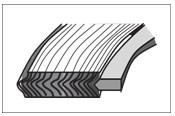

Style CGI: Fitted with an internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion.

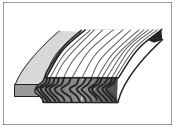

Style R: Inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies.

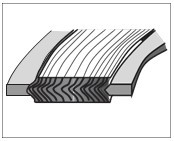

Style RIR: Solid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter of the gasket. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion at flange faces. Suitable for male and female pipe flanges.

| Material | Minimum | Maximum | Abbreviation | ||

|---|---|---|---|---|---|

| °F | °C | °F | °C | ||

| 304 Stainless Steel | -320 | -195 | 1,400 | 760 | 304 |

| 316L Stainless Steel | -150 | -100 | 1,400 | 760 | 316L |

| 317L Stainless Steel | -150 | -100 | 1,400 | 760 | 317L |

| 321 Stainless Steel | -320 | -195 | 1,400 | 760 | 321 |

| 347 Stainless Steel | -320 | -195 | 1,700 | 925 | 347 |

| Carbon Steel | -40 | -40 | 1,000 | 540 | CRS |

| 20Cb-3 (Alloy 20) | -300 | -185 | 1,400 | 760 | A-20 |

| HASTELLOY® B 2 | -300 | -185 | 2,000 | 1,090 | HAST B |

| HASTELLOY® C 276 | -300 | -185 | 2,000 | 1,090 | HAST C |

| INCOLOY® 800 | -150 | -100 | 1,600 | 870 | IN 800 |

| INCOLOY® 825 | -150 | -100 | 1,600 | 870 | IN 825 |

| INCONEL® 600 | -150 | -100 | 2,000 | 1,090 | INC 600 |

| INCONEL® 625 | -150 | -100 | 2,000 | 1,090 | INC 625 |

| INCONEL® X750 | -150 | -100 | 2,000 | 1,090 | INX |

| MONEL® 400 | -200 | -130 | 1,500 | 820 | MON |

| Nickel 200 | -320 | -195 | 1,400 | 760 | NI |

| Titanium | -320 | -195 | 2,000 | 1,090 | TI |

Material used for filler strips are as following for spiral wound gaskets.

| Material | Minimum | Maximum | Abbreviation | ||

|---|---|---|---|---|---|

| °F | °C | °F | °C | ||

| Ceramic | -350 | -212 | 2,000 | 1,090 | CER |

| Flexible Graphite | -350 | -212 | 950 | 510 | F.G. |

| PTFE | -400 | -240 | 500 | 260 | PTFE |

| Verdicarb (Mica Graphite) | -350 | -212 | 350 | 175 | VC |